ルミナスター

業界トップレベルの機能性

遮熱・断熱塗料

高い断熱機能で、冬は暖房効果を、夏は冷房効果を高めます!

快適なライフスタイルを実現!

冬は暖かく

【保温・暖房効果】

・断熱機能が室内の暖気の逃げを抑え建物を冷気から守ります。

また、結露を抑え、カビの発生を防ぎます。

【暖房エネルギー20~40%削減】

【ルミナスター塗膜】

・建物内面温度低下抑制

夏は涼しく

【涼・冷房効果】

・太陽光近赤外線を高率で反射し建物を熱くしません。

断熱効果が建物内への熱の侵入をさらに5℃以上低下させます。

【消費電力30~40%削減】

【ルミナスター塗膜】

・建物の温度上昇抑制

用途・適用範囲

街中の様々な用途で活躍しています。

※柔軟性のある塗装下地にも割れ、膨れ、剥がれることなく追従します。

- 工場

- 倉庫

- プラント

- コンテナハウス

- 車庫

- 病院

- ホテル

- 商業施設

- 学校

- 体育館

- 戸建て住宅

- 集合住宅

-

畜舎

(鶏舎・豚舎・牛舎)

- 石油・ガスタンク

- 鉄塔

-

変電設備

(キュービクル)

- テント

特徴

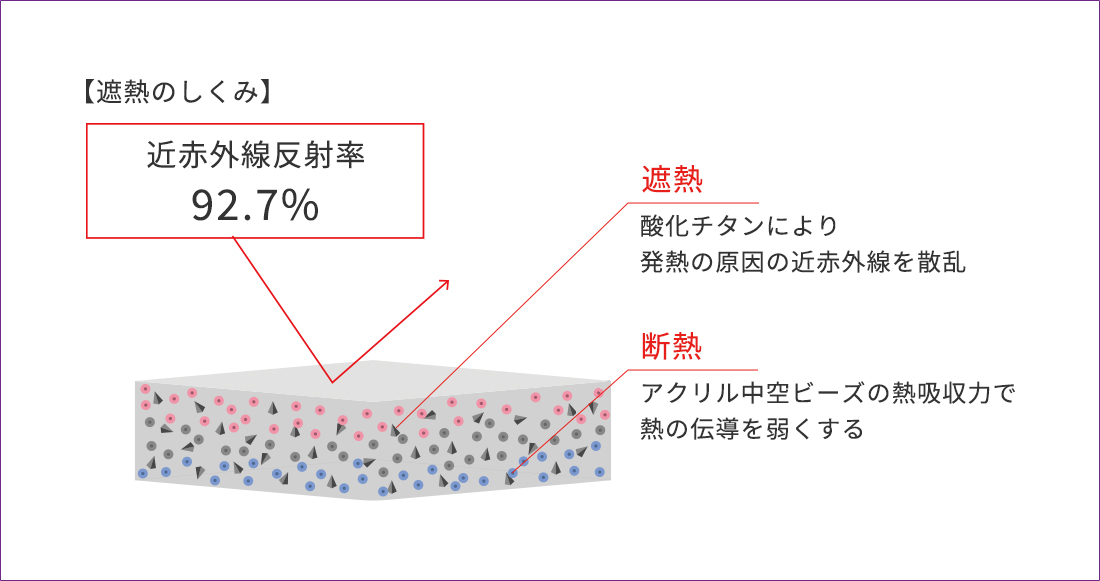

高い断熱性能【熱伝導率0.09w / (m・k)】

日射反射率(近赤外線波長域)92.7%(白)です。業界トップクラスの遮熱性能を誇ります。

遮熱残をさらに5℃断熱します。熱伝導率0.09w / (m・k)。

結露発生の抑制効果があります。

250%以上

高い伸縮性能【ゴムのように伸びる塗膜】

塗膜の伸び率250%以上、ゴムのように伸びる塗膜が建造物のクラックにも追従、美観を保ちます。

長期にわたる耐久性能

優れた耐候性【期待耐用年数15年超!】

JIS K 5600-7-7促進耐候性試験で5000時間超を実現。

割れ、膨れ、剥がれ及び変色がなく長寿命、長期間に美観・省エネを保ちます。

長期にわたる接着力

強い粘着力【JIS規格の4倍】

JIS規格の4倍の付着力で、長期間剥げることなくご使用いただけます。

建物内の温度を保持

魔法瓶効果で、夏も冬も建物内の温度を保持します。

環境への負荷がない

水性塗料ですので環境への影響、人体への影響負荷がありません。F☆☆☆☆規準の1/10以下<ホルムアルデヒド0.4μg(㎡・h)>

優れた防水性、消音性

防水性があります。

省エネ塗装を兼ねた雨漏れ対策が可能です。

また、消音性能がありますので塗装面外部からの音を軽減します。

省エネ

建物を温度変化(部材変化)、紫外線劣化から守り、結露を抑制し部材の腐食を防ぎ、省エネを実現。

建物を延命し、経済効果を生み出します。

遮熱効果について

ルミナスターは、遮熱性の高い顔料で建物を熱くする太陽の近赤外線を高率で反射し、夏季の建物を涼しく冷房効率を高め、冬季は断熱機能が建物の冷えを抑え、室内の暖房高率を高めます。高耐久性樹脂を採用、耐久性に優れています。

また、断熱機能をプラスしていますので、より高い効果を発揮します。

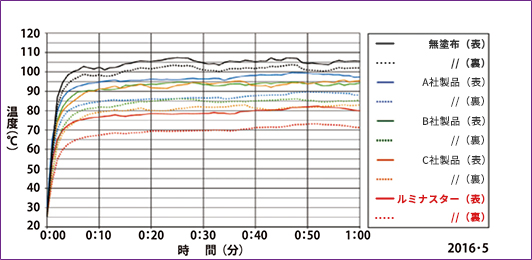

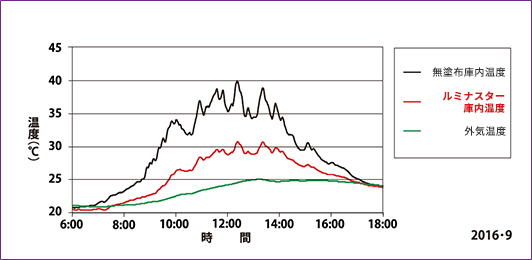

【遮熱断熱実証実験:1】

100W電球を用いた鋼板加熱実験により、ルミナスター塗布後と無塗布の温度差は20~25℃の結果が得られ、業界トップクラスの性能が実証されました。

【遮熱断熱実証実験:2】

試験用倉庫<W890・D470・920(mm)>にルミナスター塗布後と無塗布の空間温度は10℃程度の温度差が計測されました。

仕様

【商品仕様】

| 材料 | 塗料名 | 重量 | 膜厚目安 (mm) | 塗布量 (kg / ㎡) | 塗装面積 (㎡ / 缶) | 適用下地ほか | 特徴・注意 |

|---|---|---|---|---|---|---|---|

| 主材 | ルミナスター(白) |

12kg | 0.4 | 0.3 | 40 | あらゆる素材に適応可能 | 断熱剤が缶上部に浮いています。 パワーミキサーで充分に攪拌して塗装してください。(淡彩色) |

| ルミナスター ライトカラー |

12kg | 0.4 | 0.3 | 40 | あらゆる素材に適応可能 |

【色見本】

主材:標準色

- ホワイト

- スモークホワイト

- シルバーグレー

- グレー

- ブロンドイエロー

- アーモンドベージュ

- セピアブラウン

- アイスグリーン

- ライトブルー

主材:調色対応

- パールグレー

- ミルキーホワイト

- アイボリー

- クリームイエロー

- ピーチイエロー

- ライトベージュ

- ベージュ

- エクルベージュ

- サンドベージュ

- パールブラウン

- ライトブラウン

- パーチグリーン

- スプリンググリーン

- ライトグリーン

- アクアグリーン

素地調整

高圧水洗またはデッキブラシ等により、浮き、劣化塗膜、油、汚れ、付着物は完全に除去し、清浄な面としてください。

錆は完全除去し、錆止め塗装を行ってください。

傷、不陸、目違い等は補修、調整を行ってください。

塗装下地が雨や夜露等で濡れている場合は十分乾燥を行うか、モップ等で水を良く拭き取ってください。

塗装下地は良く乾燥させてください。

【塗装仕様】

※塗装間隔(23℃・50%)

※基材が木材の場合は、木材用シーラーで下塗りを行い、ルミナスターを塗装してください。

|

水を吸わない塗装下地の場合 |

|

|---|---|

| 主材塗 ルミナスター |

・塗装間隔工程間1H・塗装回数2~3回・希釈率0~5%・塗装間隔完全硬化24H |

| 塗装方法 | ・刷毛・ローラー・エアーレスガン |

| 水を吸収する塗装下地の場合 スレート、コロニアル、カラーベスト屋根、コンクリート、モルタル壁等 |

|

|---|---|

| 下塗 シーラー |

・塗装回数1~2回・塗装間隔工程間1~2H |

| 上塗 ルミナスター |

・塗装回数2~3回・希釈率0~5%・塗装間隔完全硬化24H・塗装間隔工程間1H |

| 塗装方法 | ・刷毛・ローラー・エアーレスガン |

| 濃色仕上げの場合 戸建て住宅の屋根等(鋼板屋根の場合は下塗不要です) |

|

|---|---|

| 下塗 シーラー |

塗装回数1~2回・塗装間隔工程間1~2H |

| 中途 ルミナスター |

・希釈率0~5%・塗装間隔工程間1H・塗装回数2~3回・塗装間隔完全硬化24H |

| 上塗 カラートップ |

・希釈率0~5%・塗装間隔工程間3~4H・塗装回数1~2回・塗装間隔完全硬化24H |

| 塗装方法 | 刷毛・ローラー(中毛・短毛)・エアーレスガン |

| 防水・防水シート塗装下地の場合 屋上等のウレタン防水、塩ビ防水シート |

|

|---|---|

| 下塗 プライマー |

塗装回数1回・希釈率0~5%・塗装間隔工程間7H~ |

| 上塗 ルミナスター |

・塗装回数2~3回・塗装間隔工程間1H・塗装間隔完全硬化24H・希釈率0~5% |

| 塗装方法 | ・刷毛・ローラー・エアーレスガン |

標準施工要領書

①ルミナスター商品構成(全て水性塗料で構成しています)

| 材料 | 塗料名 | 容量(缶) (kg) | 塗装間隔(23℃、50%) | 塗装回数 (回) | 塗布量 (kg/㎡) | 塗装面積 (㎡/缶) | 備考 | ||

|---|---|---|---|---|---|---|---|---|---|

| 工程時間(h) | 完全硬化(h) | ||||||||

| 下塗料(参考) | シーラー (水性浸透性シーラー) |

15 | 1-2 | – | 1 | 0.15~0.2 | 75~100 (白、無) | スレート、ALC、カラーベスト「コロニアル屋根」コンクリート、モルタル壁等、水を吸収する塗装下地に使用 | |

| プライマー (可塑剤防止プライマー) |

15 | 7 | – | 1 | 0.15~0.2 | 75~100 (白) | シート防水、ウレタン防水上にルミナスターを塗布する場合に使用(ブリード抑止用) | ||

| 主材 | ルミナスター基本色 | 12 | 1 | 24 | 2-3 | 0.3 | 40 | 白 | 鉄板等、水を吸収しない塗装下地の場合、直接塗布しても十分な接着力があります。 錆がある場合は通常の錆止め処理が必要です。 |

| ルミナスター ライトカラー |

12 | 1 | 24 | 2-3 | 0.3 | 40 | 淡彩色 | ||

②施工要領と注意

(1)下塗材(水性浸透性シーラー)施工

・吸水性のある塗料下地(RC、ALC、コンクリート、モルタル、カラーベスト「コロニアル」等に使用、旧塗膜との密着強化)

・養生目安時間1~2時間

・錆止め効果はありません。

(2)主材(ルミナスター)施工

a.注意

・比重の軽い中空ビーズを混入している一液性塗料ですが、缶を開けると中空ビーズが上部に浮いた状態となっています。

分解している訳ではありません。

・施工前に必ず電動攪拌機にて缶内の塗料の上部、下部が良く混合するよう(1~2分)攪拌してください。

棒では絶対に混合できません。

・この攪拌作業は、断熱効果を均一にし、接着力、弾力性、耐久性のある塗膜とするために重要なポイントです。

1回 / 日の攪拌で十分です。

b.希釈

■ローラー刷毛による塗装

・過度の希釈は成膜不良を起こしますので注意してください。

・冬季や塗装面が40℃以下の場合は希釈は不要ですが、状況に応じて希釈して塗装してください。

・夏季やその前後の気温が高い季節の塗装時は、下地の温度により水600~800cc / 缶を入れ、よく攪拌して塗装してください。

高温の塗装下地の場合、水分が蒸発してベタ付き、平滑な塗膜になりにくくなります。

[希釈の目安]下地の温度50℃→水300cc / 缶 70℃→水600cc / 缶

■エアレスガンによる塗装

・水600cc / 缶程度で希釈し、よく攪拌して塗装してください。

スムーズに吸付塗装できます。

c.塗装容量

■ ローラー刷毛、刷毛による塗装

[鉄板等塗布面が滑りやすい箇所に施工する場合]

・1回目は滑って膜厚がつけにくい場合があります。

・ローラー刷毛、刷毛でしごくより、塗料を置いて行く要領で塗布すると厚塗りができます。

・2~3回塗りで仕上げることを心がけてください。

■エアレスガンよる塗装

・高粘度塗料対応のエアレスポンプを使用してください。

[ポンプ出力]8l / min、150kgf / ㎠、900W程度

[チップ口径]0.6mm程度(施工面積や場所等により選定してください)

※岩田塗装機、清和産業等のメーカーがあります。

塗装機器の選定には塗装機器メーカーによく確認して適正な機器を選定してください。

※厚塗注意:一度厚塗りしますと塗膜に亀裂が発生する恐れがあります。

必ず2回塗以上で仕上げてください。

※乾燥時間:気温や天候、湿度、風の有無等により乾燥時間は変わります。

塗装面の乾燥状態を指触検査し指紋の付着がないことを確認して上塗りをしてください。

※缶の側面の乾いた塗料は混ぜないでください。

塗面に凸ができます。

※主剤は艶消し仕上げとなります。

まずはお試しください!ルミナスターのサンプル受付中

私たちはルミナスタ―の実績が増えるたびに良い素材であることを日々実感しております!

お客様の職場環境改善、経費削減にご協力出来たら幸いです。

サンプルは約600mL(約2m2分)5000円(送料込)で対応しております。

是非一度、お手に取ってこの商品を体感、お試しください。

ルミナスターが、環境問題に取り組む世の中に少しでも貢献出来たら幸いです。